Zirconium dioxide (ZrO2), also called zirconia, is an incredibly versatile material with impressive properties. It boasts a high melting point, excellent corrosion resistance, wear resistance, and outstanding electrical conductivity.

While traditionally used in refractory materials and ceramic pigments, ZrO2 has found its way into advanced applications like electronic ceramics, functional ceramics, and structural ceramics.

Physical and Chemical Properties of Zirconium Dioxide

Physical Properties

Zirconium dioxide is known for:

- High melting and boiling points

- High hardness

- Excellent electrical insulation at room temperature

What’s fascinating is that at higher temperatures, ZrO2 transforms into a remarkable conductor of electricity.

This material exists in three crystalline forms, making it a polymorphic oxide:

- Monoclinic phase (m-ZrO2): Stable at low temperatures.

- Tetragonal phase (t-ZrO2): Forms at temperatures above 1000°C.

- Cubic phase (c-ZrO2): Dominates from 2370°C until the melting point.

As ZrO2 heats up, it shrinks, and as it cools, it expands. To prevent these volume changes during use, stabilizers like Y2O3, CaO, MgO, CeO2, and other rare earth oxides are added. These stabilizers help maintain the crystal phase, keeping the material stable and preventing transformations that could cause damage.

For specific applications, the amount of stabilizer varies. For example, stabilizer content typically ranges from 7-14% for Y2O3 to >13% for CeO2, ensuring ZrO2 products are tailored for diverse needs.

Chemical Properties

Zirconium dioxide offers excellent chemical stability. Being a weakly acidic oxide, it resists damage from alkaline solutions and most acids—except for harsh ones like hot concentrated H2SO4, HF, and H3PO4.

ZrO2 crucibles can melt metals like potassium, sodium, aluminum, and iron without reacting, even at temperatures above 1900°C. However, molten alkali silicates or silicates containing alkaline earth metals can corrode ZrO2 at high temperatures.

Under extreme conditions, such as high temperatures in a vacuum, ZrO2 reacts with carbon, hydrogen, or nitrogen to form zirconium carbide, hydrides, or nitrides, respectively.

Preparation Methods of Zirconium Dioxide Powders

1. Co-precipitation Method

This is the most popular method for producing nano-sized zirconium dioxide because it’s simple, cost-effective, and easy to control. It involves:

- Mixing a zirconium salt solution (e.g., ZrOCl2·8H2O) with stabilizers and dispersants.

- Adding a precipitant (e.g., ammonia) to form zirconium hydroxide gel.

- Aging, filtering, washing, drying, and calcining the gel to produce ZrO2 powder.

2. Hydrothermal Method

This method involves mixing zirconium salts (e.g., ZrOCl2·8H2O) with ammonia solution and controlling the pH. After hydrothermal processing, the product is filtered, washed, and dried to create ZrO2 powder.

3. Microemulsion Method

Here, a reverse micelle solution is formed by mixing zirconium salts, stabilizers, and surfactants. The resulting precipitate is filtered, washed, dried, and calcined to produce zirconium dioxide powder.

4. Electrofusion Method

This method involves melting zirconium-containing materials (e.g., zircon sand) with stabilizers and clarifying agents in an electric arc furnace. The cooled and ground material produces ZrO2 powder with minimal contamination.

5. Other Methods

Techniques like the sol-gel method are also used to prepare zirconium dioxide powders for specialized applications.

Applications of Zirconium Dioxide

1. Zirconium Dioxide Refractories

Zirconium Dioxide Crucibles

With a melting point of 2700°C, ZrO2 crucibles can handle platinum group metals, quartz glass, and salts without reacting, even at ultra-high temperatures.

Zirconium Dioxide Refractory Fibers

These fibers can withstand temperatures above 1600°C for long periods, offering better thermal insulation and stability than alumina or mullite fibers.

Zirconium Dioxide Kiln Materials

ZrO2 is critical in large glass tank furnaces, extending the service life of equipment thanks to its outstanding heat resistance.

2. Zirconium Dioxide Structural Ceramics

Zirconium Dioxide Ceramic Bearings

These bearings resist wear, corrosion, and extreme temperatures, making them perfect for harsh environments.

Zirconium Dioxide Ceramic Valves

ZrO2 valves excel in wear resistance, corrosion resistance, and thermal shock endurance.

Zirconium Dioxide Grinding Materials

Grinding balls made of ZrO2 improve efficiency and reduce contamination during grinding processes.

3. Zirconium Dioxide Functional Ceramics

- Ceramic balls for ball-point pens: Durable, smooth, and reliable.

- Ceramic knives: Resistant to wear and corrosion, with a jade-like finish.

- High-temperature heating elements: Conductive at high temperatures and effective for extreme applications.

- Bioceramics: Used for dental crowns, offering strength, aesthetics, and biocompatibility.

- Coating materials for turbines: Used in high-performance engines.

- Communication materials: Key components in fiber optic connectors.

- Oxygen sensors: Reliable for advanced monitoring applications.

4. Zirconium Dioxide Decorative Materials

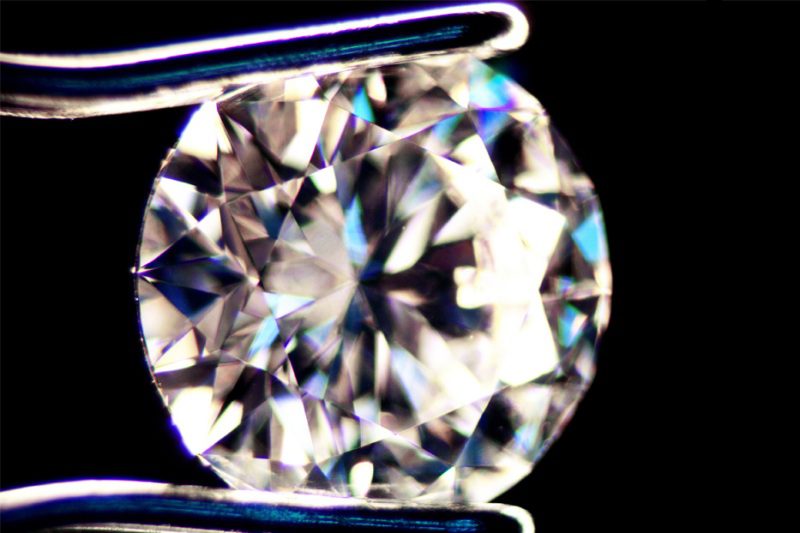

Zirconium Dioxide Gemstones

Cubic zirconia is a stunning, affordable alternative to diamonds, with excellent optical properties.

Zirconium Dioxide Ceramic Jewelry

From earrings to watch bezels, ZrO2 adds elegance and durability to modern jewelry.

5. Other Applications

- Composite materials: Combining ZrO2 with other materials enhances performance.

- Additive for ceramics: Improves glaze properties, crack resistance, and chemical stability.

- Raw material for zirconates: Essential for high-temperature and electronic uses.

Why Choose Zirconium Dioxide?

Whether you’re in manufacturing, electronics, or advanced ceramics, ZrO2 delivers unmatched performance. Its versatility, stability, and resistance make it a top choice for industries worldwide. CCTC will give you a professional customized material solution.

Pro Tip: When selecting ZrO2, consider the stabilizer content and application requirements to ensure optimal performance for your specific needs.

Zirconium dioxide isn’t just a material—it’s a solution for advanced challenges.