Why Choose Us

Guided by customer needs Provide diversified product solutions

Based on quality assurance as a prerequisite Assist customers in creating highly reliable and high-quality products

Guided by technological innovation Cooperate with customers to explore new product markets

Putting customer value at the center Provide value-added services to customers

Based on the principle of openness and inclusiveness Realize multidimensional cooperation and win-win outcomes

Equipment self-made capability

300+

10000

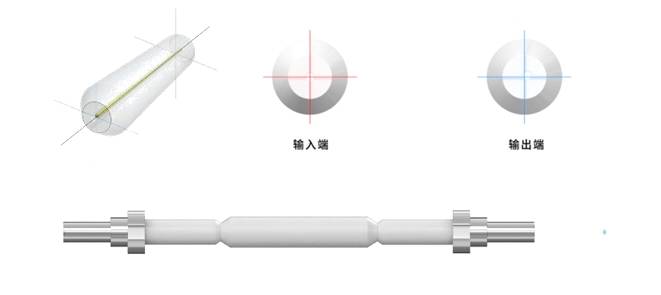

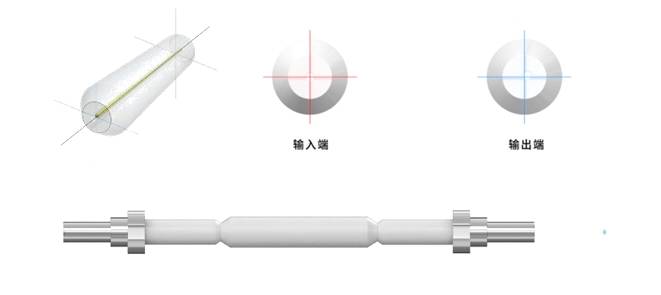

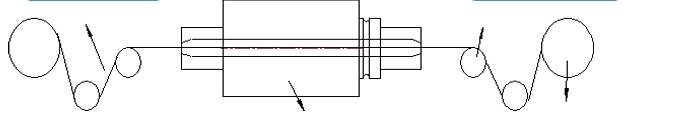

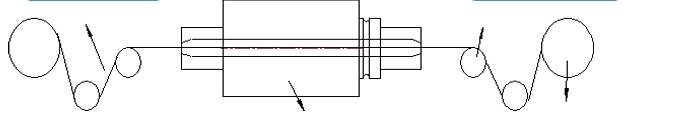

Extrusion

Using extrusion molding technology to produce various non-standard ceramic long tubes, It is currently the only domestic product with high-precision extrusion of ceramic powder Enterprises with advanced technology

Extruded long tube blank size | |

| name | Size (mm) |

external diameter | φ1.0-4.0 |

internal diameter | φ0.1-1.0 |

| length | <180 |

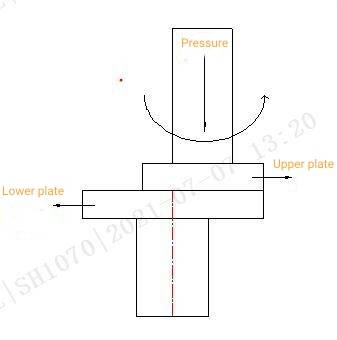

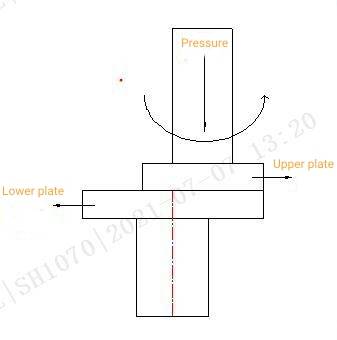

Outer diameter grinding

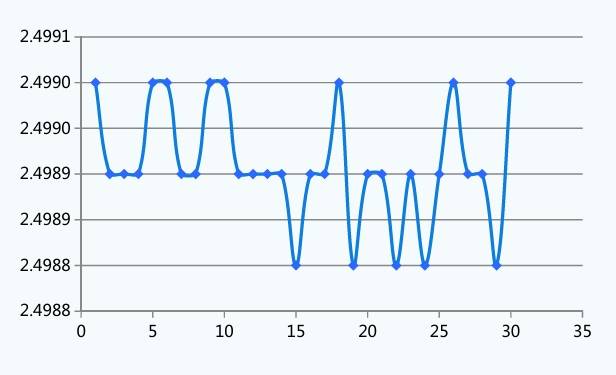

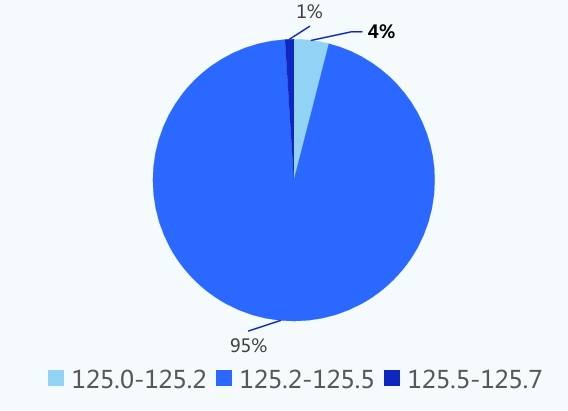

Machining accuracy of outer diameter

Place the product in a circular fixture and add grinding fluid to allow the processed product to swing freely

diameter accuracy

diameter accuracy

diameter

raccuracy

Inner diameter grinding

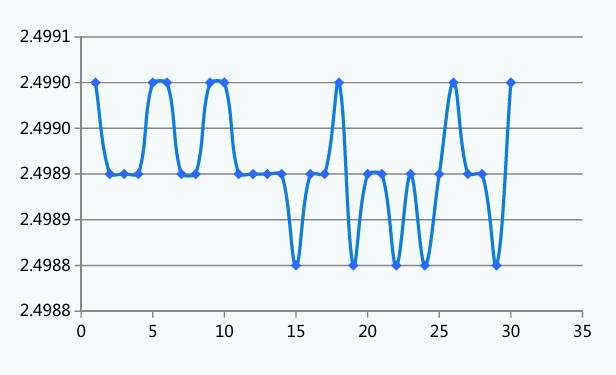

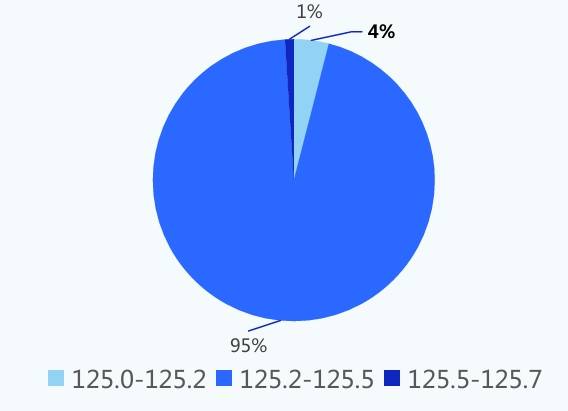

Machining accuracy of inner diameter

Using a precision spindle grinding head to rotate at high speed, the steel wire with accompanying grinding fluid repeatedly moves to make the product

The inner hole continues to expand, allowing the workpiece to obtain the required geometric dimensions

diameter accuracy

diameter accuracy

diameter

raccuracy

We Are Available For You

Call Us or Fill the Form

Don’t hesitate to contact us

Mon-Fri: 9:00 - 18:00 / Closed on weekends

Our Strength

Build an intelligent production system and facilities to achieve production automation and intelligence.

Automation

Through automatic feeding systems, robotic arms, AGV carts and other equipment, the intelligent workshop achieves full process automation of production from raw material addition, injection molding, automatic material picking and swinging, kiln sintering, etc.

Intelligentization

By utilizing the underlying system design, different devices such as components, perception, manufacturing, and transportation within the workshop can be interconnected and interconnected. Based on this, a vertically integrated environment that is "measurable, controllable, producible, and manageable" can be constructed, and the control room can observe and control the production status of the entire workshop at any time.