Key Features

- High Hardness and Wear Resistance

- Zirconia ceramic blades are several times harder and more wear-resistant than traditional metal blades.

- Maintain sharpness even with frequent use, reducing replacement frequency and extending tool life.

- Eco-Friendly and Health-Safe

- Made from high-purity zirconia materials, free from harmful chemicals.

- Does not rust, release toxins, or contaminate food or materials being cut, ensuring safety and environmental friendliness.

- Easy to Clean

- Non-stick surface prevents food or debris from adhering to the blade.

- Simple to rinse and clean, saving time and maintaining hygiene.

- Outstanding Durability

- Resistant to corrosion, oxidation, and magnetization.

- Withstands exposure to acids, alkalis, and organic substances, making it suitable for various challenging environments.

- Sharp and Lightweight

- Razor-sharp cutting edges ensure effortless slicing and cutting tasks.

- Lightweight design makes it easy to handle, reducing fatigue during extended use.

- Elegant and Modern Design

- Smooth, polished surface with a jade-like appearance, combining ancient ceramic craftsmanship with modern technology.

- Adds sophistication to kitchens, laboratories, and industrial tools.

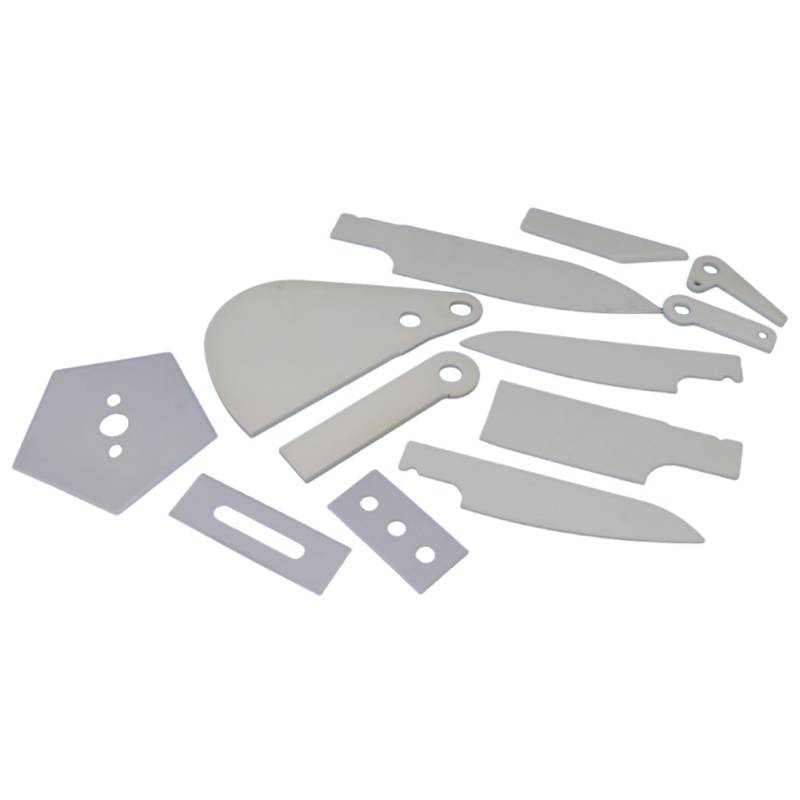

Applications

Zirconia Ceramic Blades are widely used in various fields, including:

- Kitchen Tools

- Fruit knives, chef knives, and scissors designed for cutting fresh produce and cooked foods without leaving metallic odors or rust marks.

- Ideal for preparing raw and delicate foods.

- Industrial Cutting Blades

- Trimming, scraping, and other cutting tasks in manufacturing and engineering.

- Specialized blades for textile cutting, battery separator trimming, and capsule cutting machines.

- Medical Devices

- Surgical blades and components for precision cutting.

- Office and Commercial Use

- Receipt cutters and shredders equipped with durable ceramic blades.

- Maintenance Tools

- Ceramic sharpening blocks for honing both traditional and ceramic blades.

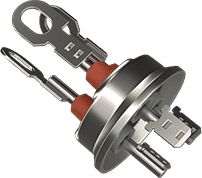

Manufacturing Process

Zirconia ceramic blades are crafted using advanced techniques:

- A mixture of zirconia and alumina powders is pressed under 300 tons of pressure in a mold and sintered at 2000°C.

- The blades are polished with diamond tools to achieve a sharp edge.

- Handles are added to complete the product, resulting in a blade with high hardness, density, and resistance to extreme temperatures.

Reviews

There are no reviews yet.