I. Introduction to Zirconia Ceramic

Zirconia ceramic, also known as ZrO2 ceramic, is a crucial advanced ceramic material with a wide range of applications in modern high-tech industries.

Its unique properties, such as high melting point, excellent hardness, wear resistance, and insulating properties, make it a popular choice for various sectors.

Zirconia ceramic is produced by purifying zirconium ore, with the world’s proven zirconium resources amounting to approximately 19 million tons.

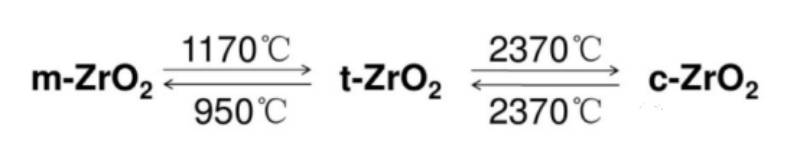

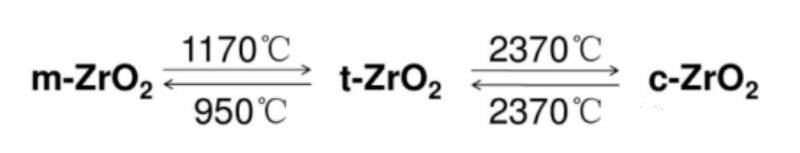

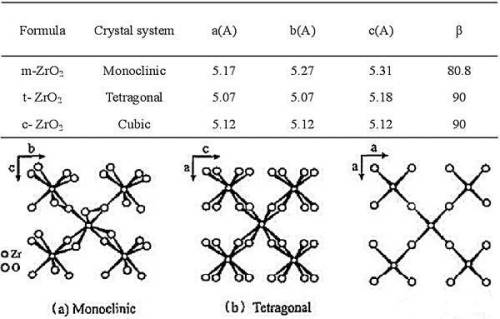

ZrO2 exists in three crystalline forms: monoclinic (m-ZrO2) at low temperatures, tetragonal (t-ZrO2) at medium temperatures, and cubic (c-ZrO2) at high temperatures. These forms can transform into each other within different temperature ranges, contributing to the material’s phase transformation toughening characteristics.

II. Properties and Characteristics of Zirconia Ceramic

Zirconia ceramic exhibits a combination of desirable properties, making it suitable for various high-tech applications:

- High melting point (2715°C) and chemical inertness

- High hardness (Mohs hardness of 8.5) and excellent wear resistance

- Relatively high strength (up to 1500 MPa) and toughness (1-35 MPa·m¹/²)

- Low thermal conductivity (1.6-2.03 W/(m·K)) and low coefficient of thermal expansion

- Excellent electrical properties, with a dielectric constant three times that of sapphire

- Non-metallic nature, resulting in no electromagnetic signal shielding

- Scratch resistance, good heat dissipation, strong processability, and suitability for mass production

III. Powder Preparation Processes for Zirconia Ceramic

The performance of zirconia ceramic depends on high-quality zirconia powder. Several methods are used to prepare zirconia ceramic powder:

- Coprecipitation Method: Simple equipment, low production cost, and easy to obtain nano-sized ultrafine powders with high purity. However, it may result in poor powder dispersion and low sintering activity due to hard agglomeration.

- Hydrolysis Precipitation Method: Divided into zirconium salt hydrolysis precipitation (simple operation but long reaction time and agglomeration issues) and zirconium alkoxide hydrolysis precipitation (minimal agglomeration and excellent purity but complex and costly raw material preparation).

- Hydrothermal Method: Produces extremely fine powders with narrow particle size distribution and minimal agglomeration. However, the equipment is complex and expensive, making large-scale industrial production difficult.

- Sol-Gel Method: Yields sub-micrometer or finer powders with narrow size distribution, high purity, and uniform composition. Disadvantages include high raw material costs, environmental pollution, and difficulties in process control.

IV. Typical Applications of Zirconia Ceramic

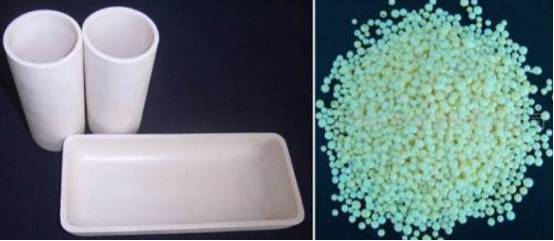

Zirconia ceramic finds applications in various fields, including:

1. 3C Electronics, such as mobile phone back covers and structural components

2. Smart Wearable Devices, like high-end ceramic watches

3.Optical Communications, as ceramic ferrules and sleeves in optical fiber connector assemblies

4.Biomedical Field, for dental restorative materials and surgical instruments

5.Automotive Field, for thermal insulation in engine combustion chambers (potential future application)

6.Jewelry Field, mixed with precious metal alloy powders for lightweight, wear-resistant, and hypoallergenic jewelry

7. Daily Life, as ceramic bowls, spoons, vases, and knives

8. Other Fields, such as ceramic bearings, cutting tools, refractory crucibles, and components in petroleum, chemicals, machinery, and aviation industries

V. Major Powder Manufacturers of Zirconia Ceramic

The market for zirconia ceramic powders is currently dominated by imported products from renowned manufacturers like Saint-Gobain, Tosoh (Japan), Maruwa (Japan), and Samsung.

However, domestic powder enterprises such as CCTC are gradually increasing their market share through continuous expansions in the zirconia ceramic industry.