Deyang Sanhuan Technology Co., Ltd. has been deeply engaged in glass packaging and ceramic metallization technology for 15 years, with a total area of 20,000 square meters and 386 employees (including 51 managers and 30 technicians); it has several major technical platforms such as glass packaging, ceramic metallization, and ceramic and metal brazing. With the support of a strong scientific research team and a complete full-process production line, customized research and development can be carried out according to customer needs.

1970

1972

1992

2007

2016

2019

2020

2022

Before the 1970s

1992

1998

2014

2017

2020

2021

2022

& Customized Products For You

Application: Suitable for precision machining of ceramics, sapphires, glass and other materials

Processing scope:

500×400mm

Quantity: 1600 units

Application: It can achieve high-precision, high-speed, and low-power cutting of materials such as glass, ceramics, sapphire, etc

Processing scope:

220×400×100mm

Quantity: 33 units

Application: It can perform very precise and stress free micro scale processing on thin film materials such as ceramics, sapphires, glass, and composite materials

Processing scope:

300×240mm

Quantity: 30 units

Application: It can be widely used for marking and processing vector and bitmap images on the surfaces of materials such as ceramics, glass, metal, and plastic

Processing scope:

200×200mm

Quantity: 30 units

Application: Suitable for precision machining of ceramics, sapphires, glass and other materials

Processing scope:

600×200mm

Quantity: 50 units

Application: Suitable for chemical mechanical grinding of hard and brittle materials such as ceramics and sapphires to remove machining marks, reduce surface roughness, and achieve a smoother surface

Processing scope:

ϕ400mm

Quantity: 300 units

Application: It can achieve printing and coating of silver paste, molybdenum manganese paste, tungsten paste and other pastes on ceramic parts

Quantity: 5 units

Application: Atmosphere protection sintering for metalizing slurries

Quantity: 5 units

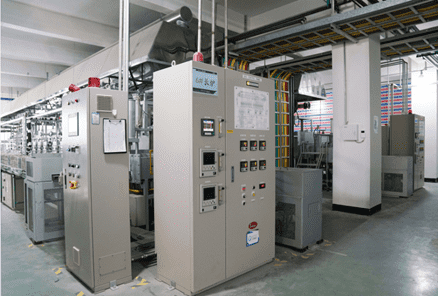

Application: Weldable coatings such as nickel, tin, and gold can be electroplated on the surface of metalized slurries

Quantity: 3 pieces

We Are Available For You

Surface treatment technology

1. Having chemical plating/electroplating technology, nickel layer, tin layer, copper layer, gold layer, etc. can be plated on the surface of metalized ceramics and metal parts to ensure that the product has high rust prevention performance and reliable welding performance;

2. The process is mature and stable, and can be customized according to customer coating requirements.

Application:It can achieve cutting and forming of solder materials with various thicknesses, compositions, and shapes

Quantity: 5 units

Application:Used for brazing between ceramic and metal materials of the same or different types under special atmospheres or vacuum conditions

Quantity: 3 units

Application: Used for brazing between ceramic and metal materials of the same or different types in a protective atmosphere

Quantity: 15 pieces

Office Contacts

We envision a global industry that protects and restores the environment and enhances lives.

NY 10018 USA.

1504 Parrill Court, Crown Point

IN, Indiana

219-616-6578

219-765-9940

1504 Parrill Court, Crown Point

IN, Indiana

219-616-6578

219-765-9940

2867 Rowes Lane

GA, WILLACOOCHEE

270-586-3427

912-895-3513

2867 Rowes Lane

GA, WILLACOOCHEE

270-586-3427

912-895-3513

771 Ward Road, WOODINVILLE

WA, Washington

915-225-3070

206-849-5482

771 Ward Road, WOODINVILLE

WA, Washington

915-225-3070

206-849-5482

2682 Clark Street, GLEN FLORA

WI, Wisconsin

630-967-1785

414-388-5856

2682 Clark Street, GLEN FLORA

WI, Wisconsin

630-967-1785

414-388-5856

3907 Church Street, Brooklyn

NY, New York

718-492-9271

347-422-5773

3907 Church Street, Brooklyn

NY, New York

718-492-9271

347-422-5773